Decarbonization at U. S. Steel - www.ussteel.com

PROTECTING OUR PLANET

DECARBONIZATION AT U.S.STEEL

Progress

- Global emissions intensity decreased from 2022 to 2023

- Reduced our Scope 2 emissions through the additional use of renewables

- Shut down three coke batteries at Clairton Plant

- USSK will reduce up to 90,000 metric tons of CO2 emissions due to operational upgrades

- BR1 began participating in Entergy’s Green Promise tariff program

- BR1 reduced Scope 2 emissions intensity by 15% from a 2021 baseline

- Released Environmental Product Declarations (EPDs) for most of our products

- Became the first industrial company to use battery-powered

Looking Forward

U. S. Steel’s Big River Steel 2 (BR2), our second mini mill, is expected to start up in 2024

U. S. Steel’s Big River Steel Works will be able to receive up to 250 MW of solar power from the Entergy Arkansas Driver Solar project beginning in 2024 + Partnering with GTI Energy and the Department of Energy (DOE) to test an engineering-scale ROTACAP ™ CO2 capture system on real flue gas conditions at our Edgar Thomson facility

Working with the National Energy Technology Laboratory (NETL) to develop a thin film composite (TFC) membrane for industrial carbon capture for testing at our Edgar Thomson facility in 2025

Collaborating with Molten Industries Inc. and the DOE to integrate clean hydrogen produced via methane pyrolysis to reduce iron ore to iron in a direct reduction process in our blast furnaces

Partnering with Carnegie Mellon University to increase the Technology Readiness Level of the hydrogen-based direct reduction of iron oxide (DRI) process

Utilizing CarbonFree’s SkyCycle™ technology at our Gary Works facility to capture and mineralize up to 50,000 metric tons of CO2 per year

Energy

SEE OUR ENERGY-RELATED HIGHLIGHT, GOALS AND PROGRESS – CLICK HERE

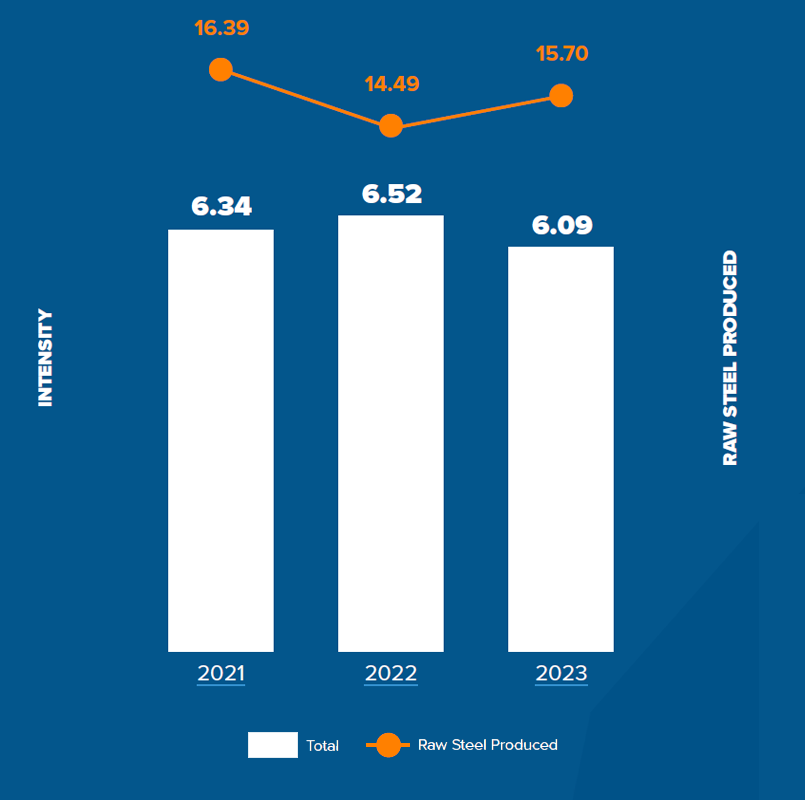

Energy (million megawatt hours) and Energy Intensity (megawatt hours/metric tons raw steel)

| USAGE | 2021 | 2022 | 2023 | INTENSITY | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|---|---|

| U.S. Operations | 76.72 | 71.94 | 72.25 | U.S. Operations | 6.44 | 6.54 | 6.17 |

| USSK Operations | 27.27 | 22.53 | 23.44 | USSK Operations | 6.10 | 6.47 | 5.88 |

| Total | 103.98 | 94.47 | 95.69 | Total | 6.34 | 6.52 | 6.09 |

U. S. Steel Annual Energy Usage Intensity and Production for the Global Operations

Intensity Units — Megawatt Hours of energy per metric ton of raw steel produced Raw Steel

Produced Units — million metric tons

Energy intensity is based on the total energy consumption in megawatt hours divided by the total quantity in metric tons of raw steel produced globally as published in the U. S. Steel Annual Report and that are converted into finished steel products.

USSK’s Digital Studio

USSK has established a “Digital Studio” — a dedicated team developing advanced analytics and artificial intelligence (AI) tools that pore over company data to provide cost- and energy-saving insights into all aspects of the business.

Solutions suggested by Digital Studio’s modeling and predictions have uncovered ways to reduce the cost of raw material procurement, fine-tune the steelmaking process to cut CO2 emissions, and lower energy usage throughout USSK’s facilities.

Entergy Arkansas

We partnered with Entergy Arkansas on their Driver Solar Project, a new 250-megawatt AC (or 312 MW DC) renewable energy plant developed by Lightsource bp. The plant will be situated adjacent to U. S. Steel’s Big River Steel Works in Osceola, Arkansas. Once completed in 2024, the renewable energy generated will power the production of verdeX® steel, our advanced sustainable steel composed of up to 90% recycled steel content. Entergy Arkansas is also providing other means of accessing renewable energy to support the achievement of U. S. Steel’s long-term net-zero goal, including eliminating our Scope 2 emissions.