Customers - Products - Dent-Resistant Steel - www.ussteel.com

PRODUCTS

DENT-RESISTANT STEEL

U. S. Steel's dent-resistant products are specially designed to deliver the benefits of lightweighting with increased resilience against dents resulting from daily wear and tear.

Ongoing weight reduction efforts have driven a steady decrease in the thickness and mass of automotive components in recent years. That’s why U. S. Steel has developed new grades of steel to resist the tendency of thin-gauge exposed panels to permanently dent, the result of anything from a hail storm to stones thrown off a construction vehicle, an errant baseball throw to an out-of-control shopping cart.

Dent-resistant steels from U. S. Steel offer a combination of formability and high yield strength that is not attainable with low-carbon, mild steels or conventional high-strength steels—these are advanced, bake-hardenable steels designed to have the formability requirements needed in most exterior applications.

DENT-RESISTANT STEEL PRODUCT

FEATURES

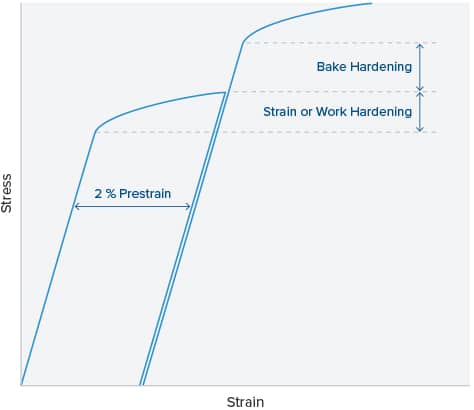

A bake-hardenable steel is any steel with the capacity for a significant increase in strength through the combination of work hardening during part formation and strain aging during a subsequent thermal cycle such as a paint-baking operation.

A combination of relatively low yield strength prior to manufacturing and high in-part strength after forming and paint baking makes bake-hardenable steels ideal for applications where dent and palm printing resistance is important. This material can be used in relatively complex deep draw or stretching operations. High in-part strength also makes bake-hardenable parts good candidates for downgauging to reduce weight.

In bake-hardenable steel, the amount of strain introduced during the forming process will largely dictate the final strength of the part. Since automotive parts—specifically exposed body panels—have a wide array of designs, there will be a corresponding disparity in the amount of strain introduced in these varying geometries. As a result, when using bake-hardenable steel, it’s important to design an adequate amount of strain into a part in order to fully utilize this material’s dent-resistant characteristics.

APPLICATIONS

- Doors

- Deck Lids

- Quarter Panels

- Fenders

- Hoods

- Roofs

TYPICAL PROPERTIES FOR BH 180 MPa

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Cold Rolled | 195 | 325 | 39 | 0.21 |

| EG | 195 | 325 | 39 | 0.21 |

| HDGI | 185 | 305 | 39 | 0.21 |

| HDGA | 185 | 305 | 39 | 0.21 |

TYPICAL PROPERTIES FOR BH 210 MPa

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Cold Rolled | 225 | 345 | 39 | 0.20 |

| EG | 225 | 345 | 38 | 0.20 |

| HDGI | 230 | 355 | 34 | 0.19 |

| HDGA | 230 | 355 | 34 | 0.19 |

TYPICAL PROPERTIES FOR BH 240 MPa

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Cold Rolled | 256 | 378 | 35 | 0.19 |

| EG | 256 | 378 | 35 | 0.19 |

| HDGI | 250 | 370 | 36 | 0.20 |

INCREASE IN YIELD STRENGTH DURING FORMING AND BAKING

DENT-RESISTANT STEEL APPLICATIONS

SUPPORTING AUTOMOTIVE

CUSTOMER SUCCESS.

At U. S. Steel, careful listening, creative thinking and cross-functional collaboration turn better steel into better solutions for our automaker customers.

LEARN MOREOur Products

Whatever your opportunity or challenge, we have a solution. Browse our product categories below to learn more.

NORTH AMERICAN FLAT-ROLLED

PRODUCTS PRICING