Customers - Solutions - Energy - www.ussteel.com

INTEGRATED ROUND SOURCING

SUSTAINABLE STEELMAKING TECHNOLOGY.

U. S. Steel commissioned its first Electric Arc Furnace (EAF) steelmaking technology in 2020 on-site at Fairfield Tubular Operations, making U. S. Steel Tubular Products fully integrated with a responsive supply chain. EAF steelmaking is sourced by scrap steel, and Fairfield Tubular Steelmaking Operations is able to procure nearly 80% of their scrap requirements from a 200-mile radius.

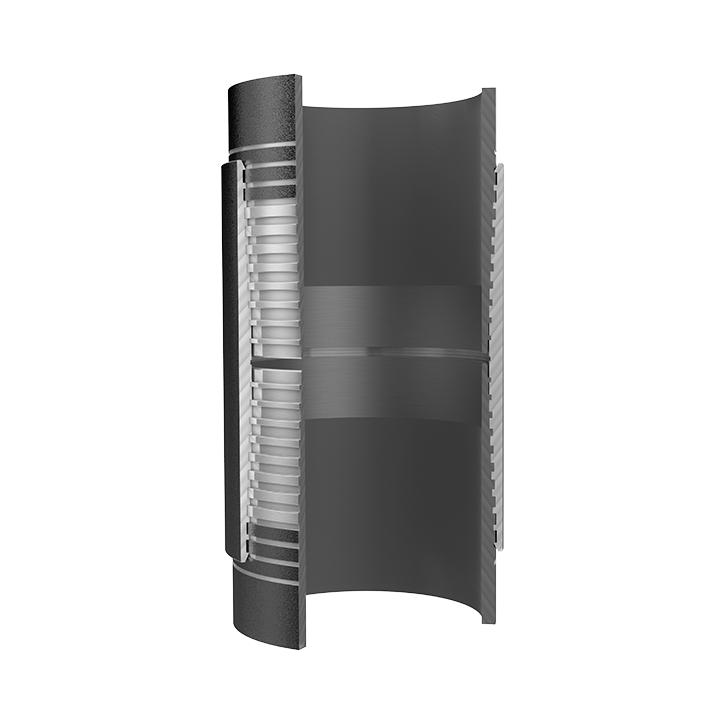

SEAMLESS PIPE

SEAMLESS MANUFACTURING

FROM START TO FINISH.

U. S. Steel Tubular Products produces high-quality seamless pipe used in oil and gas exploration and production, as well as high-volume energy transmission. Our seamless manufacturing process includes oil country tubular goods (OCTG), standard and line pipe and coupling stock.

Known for its tremendous strength and durability, our seamless pipe is manufactured to precise specifications at our American Petroleum Institute (API) licensed facilities.

PROPRIETARY CONNECTIONS

Performance, guaranteed.

We offer a new generation of connections engineered to exceed the torque, bending and compression challenges of the most extreme oil and gas environments.STANDARD AND LINE PIPE

EXCEEDING EXPECTATIONS.

U. S. Steel Tubular Products standard and line pipe offering is strong, dependable, and made to exacting specifications.

STANDARD AND LINE PIPE OFFERING

FORTIFYING AMERICAN ENERGY.

As the only fully integrated Tubular solutions provider headquartered in the U.S., our regional supply chain delivers a complete portfolio of pipe, connection technology, and services to meet the most demanding customer requirements.

LEARN MOREOCTG CONNECTIONS TOOLKIT

AN INTERACTIVE TOOL FOR

PROPRIETARY CONNECTIONS.

This interactive tool provides essential information on USSTP’s suite of proprietary connections. Pipe Body, Connection and Field Torque Properties are shown. Blanking Dimensions are also available.

U. S. STEEL TUBULAR OCTG CONNECTIONS TOOLKIT