Water - www.ussteel.com

PROTECTING OUR PLANET

Water

Each of our facilities use water for cooling and processing purposes. We use water-recycling systems that return water for reuse in operations, greatly reducing the amount of water being brought into plants. We continue to implement conservation practices to help limit our water consumption and reduce our footprint on local ecosystems and communities.

U. S. Steel's Big River Steel Works made significant investments in its water system to increase recycling of water and reduce the amount of water used per ton of steel produced. The concentrations of metals in the water discharged from the facility were lowered. In addition, improvements to Big River Steel Works' wastewater treatment plant reduced the amount of wastewater filter cake sent to landfills.

U. S. Steel is committed to responsible water use and is continuously working to improve operations that are a part of our water systems at all our facilities.

To see our water-related highlights, goals and progress, click here.

Photo: Gary Harbor Breakwater Lighthouse is located in Gary Harbor, Lake Michigan.

Data

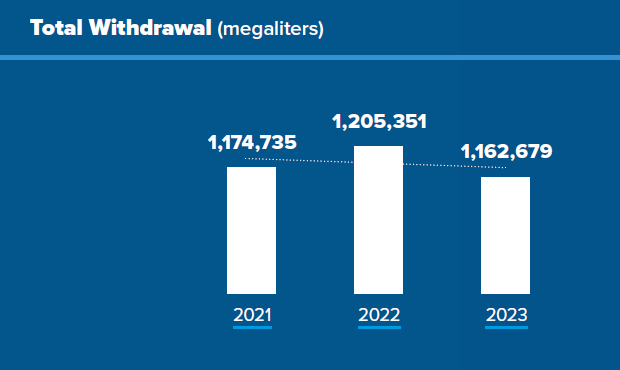

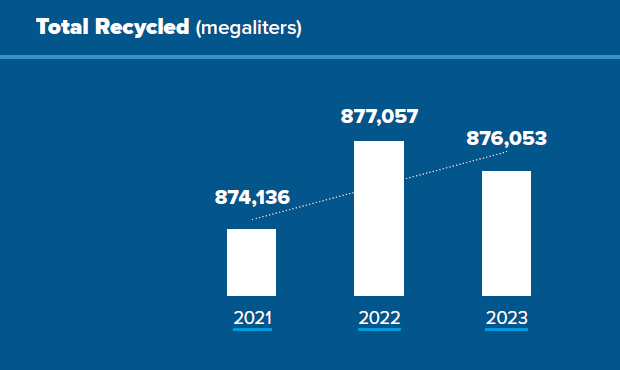

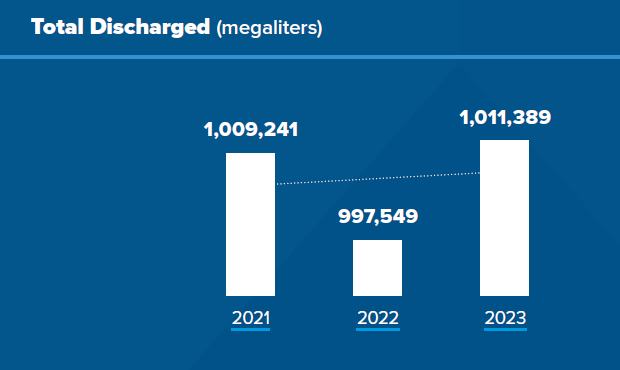

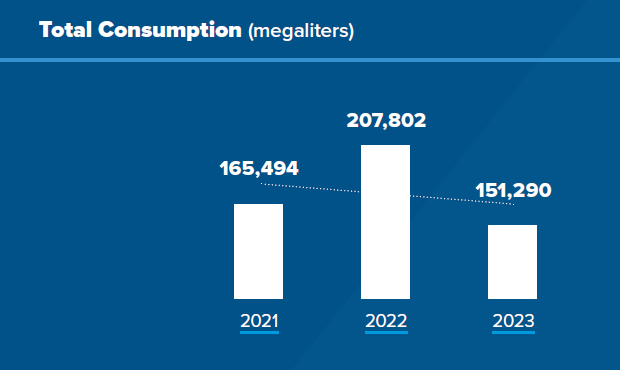

| Water (megaliters) | 2021 | 2022 | 2023 |

|---|---|---|---|

| Total withdrawal | 1,174,735 | 1,205,351 | 1,162,679 |

| Total recycled | 874,136 | 877,057 | 876,053 |

| Total discharged | 1,009,241 | 997,549 | 1,011,389 |

| Total consumption | 165,494 | 207,802 | 151,290 |

Improving Water in Minntac’s Tailings Basin

Water Stewardship Plan at

U. S. Steel’s Big River Steel Works

City Water Conservation at Great Lakes Works

Using the InCITE platform, our Great Lakes Works facility has continuously monitored plant utility usage of city water, natural gas, electricity and steam. InCITE is an environment-related platform used at some of our plants —“CITE” stands for Comply, Improve, Train, Evaluate. Utilizing this platform, Great Lakes Works has saved about 1,000 gallons of city water per minute from 2019–2023. These savings were achieved through identifying and repairing multiple underground piping leaks and converting cooling loops from trough city water to open loop service water. If the city water flow ever exceeds specific gallon-per-minute thresholds, Great Lakes Works is notified by email immediately.

These water savings also have an effect on CO2 emissions reduction. The city removes the water from Lake St. Clair, filters and treats the water, and pumps it up to the water towers. The electricity used to do this is generated by power plants. The potential reduction of carbon emissions from Great Lakes Works water savings alone is roughly 3.97 million pounds of CO2 per year.