Customers - Products - Mild Steels - www.ussteel.com

PRODUCTS

Mild Steels

U. S. Steel offers a full selection of mild steels to fit a variety of application requirements.

From highly sophisticated Extra Deep-Drawing Steel to basic Commercial Steel Type B and other grades in between, U. S. Steel has the right mild steel to meet your unique requirements. Our wide selection allows you to strike the perfect balance between cost and performance across a broad range of automotive applications.

Whether your application requires high degrees of formability and uniformity or is a simple part in an

unexposed location in the vehicle, U. S. Steel engineers can help you dial in exactly the right performance characteristics.

MILD STEEL PRODUCTS

FEATURES

With excellent uniformity and exceptional formability, Extra Deep Drawing Steel (EDDS) by U. S. Steel is produced from vacuum degassed steel to achieve a very low-carbon content. It is chemically stabilized with elements such as titanium and niobium (columbium) during production to combine the remaining residual amounts of carbon and nitrogen to make it “interstitial-free.” The final product is excellent for deep drawn parts in that the sheet exhibits a high resistance to thinning during drawing.

EDDS sheet is non-aging, thus coil breaks, strain lines and fluting during fabrication are not encountered.

- Weldability – Low-carbon level makes this a good welding candidate.

- Fatigue Performance – Relatively low yield, compared to other steels, makes this grade more susceptible to fatigue than higher strength steels.

- Denting – Relatively low yield strength, compared to other steels, may make EDDS more susceptible to denting. For additional capabilities, please check our dent-resistant steels.

- Applications – EDDS is used in applications where severe forming characteristics are required. EDDS is typically found in door inners, dash panels, body side inners and floor pans with spare tire tubs.

APPLICATIONS

- Door inners

- Dash panels

- Body side inners

- Floor pans with spare tire tubs

TYPICAL PROPERTIES FOR EDDS

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Cold Roll | 155 | 297 | 45 | 0.25 |

| EG | 168 | 304 | 44 | 0.24 |

| HDGI | 145 | 303 | 46 | 0.24 |

| HDGA | 145 | 303 | 46 | 0.24 |

FEATURES

Deep-Drawing Steel by U. S. Steel is a mild steel grade that meets improved drawability compared with DS Type B and ideal for production of parts that require severe deformation. The usual metallurgical approach is to provide DDS as a low carbon/low manganese steel chemistry combined with low amounts of residual elements. Cold-rolled and electrolytic zinc coated steels will use the following compositional limits: C-0.06 max., Mn-0.50 max., P-0.020 max. and S-0.025 max.

The Hot-Dip Galvanized and Galvannealed DDS substrate is produced from aluminum-killed steel employing special steelmaking practices. It can be produced using restricted low carbon steels or interstitial-free steels depending on the application requirement and the producing facility. DDS has forming characteristics superior to CS and FS sheet. These characteristics make it excellent for applications involving deep drawing or combinations of drawing and stretching. The Hot-Dip Galvanized and Galvannealed DDS substrate will use the following compositional limits: C-0.06 max., Mn-0.50 max., P-0.020 max. and S-0.025 max.

- Weldability – Low-carbon level makes this a good welding candidate.

- Fatigue Performance – Relatively low yield, compared to other steels, makes this grade more susceptible to fatigue than higher strength steels.

- Denting – Relatively low yield strength, compared to other steels, may make DDS more susceptible to denting. For additional capabilities, please check our dent-resistant steels.

- Applications – DDS is very similar to DS Type B. This material offers more formability to produce parts with a moderate depth of draw. Typical applications would include body sides, roofs, floor pans, reinforcements, doors, deck lids and hoods with difficult shapes

APPLICATIONS

- Body sides

- Roofs

- Floor pans

- Reinforcements

- Doors

- Deck lids

- Hoods

TYPICAL PROPERTIES FOR DDS

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Hot Roll | 207 | 317 | 36 | – |

| Cold Roll | 168 | 297 | 45 | 0.24 |

| EG | 182 | 307 | 41 | 0.23 |

| HDGI | 152 | 296 | 47 | 0.24 |

| HDGA | 152 | 303 | 45 | 0.24 |

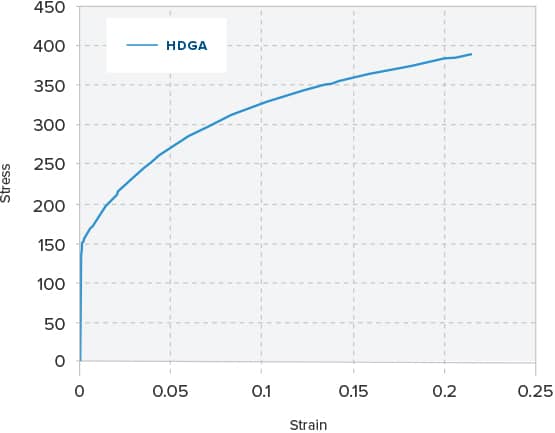

TRUE STRESS/STRAIN CURVE - DDS, HDGA

FEATURES

Drawing Steel (DS) Type B by U. S. Steel has a greater degree of ductility and is more consistent in performance than Commercial Steel Type B because of higher standards in production, selection and melting of steel. The improved ductility and uniformity of properties of Drawing Steel compared to Commercial Steel sheet means that it provides improved performance during manufacturing. If drawing depth is more severe, please refer to Deep-Drawing Steels or Extra Deep Drawing Steels.

DS Type B Replaces Drawing Quality (DQ) and Drawing Quality Special Killed Steels (DQSK). DS Type B must be ordered within the following compositional limits: C - 0.02/0.08, Mn - 0.50 max., P - 0.020 max., and S - 0.030 max.

- Weldability – Low-carbon level makes this a good welding candidate.

- Fatigue Performance – Relatively low yield, compared to other steels, makes this grade more susceptible to fatigue than higher strength steels.

- Denting – Relatively low yield strength, compared to other steels, may make DS Type B more susceptible to denting. For additional capabilities, please check our dent-resistant steels.

- Applications – DS Type B is the most common material found in automotive stampings today. This material offers the formability that is required to produce parts with some depth of draw. Typical applications would include body sides, roofs, floor pans, reinforcements, doors, deck lids and hoods.

APPLICATIONS

- Body sides

- Roofs

- Floor pans

- Reinforcements

- Doors

- Deck lids

- Hoods

TYPICAL PROPERTIES FOR DS

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Hot Roll | 217 | 331 | 34 | – |

| Cold Roll | 175 | 297 | 44 | 0.23 |

| EG | 181 | 310 | 43 | 0.22 |

FEATURES

Commercial Steel (CS) Type B is a mild steel used in many automotive applications where simple bending or moderate forming is required. This grade can be bent flat on itself in any direction at room temperature. If drawing depth is more severe, please refer to DS Type B steels.

CS Type B is susceptible to aging, which may cause problems such as stretcher strains, fluting, coil breaks (in heavy gauges), loss of ductility and increased hardness. Roller leveling this grade prior to forming will reduce the chance for stretcher strains or fluting caused by aging. However, leveling will not restore softness or ductility.

- Weldability – Low-carbon level makes this a good welding candidate.

- Fatigue Performance – Compared to other low-carbon steels, CS Type B has the highest yield strength, which means it will have a good resistance to fatigue. But higher strength steels may be better candidates for durability sensitive components.

- Denting – CS Type B is not used on exposed applications due to the aging characteristics. For dentresistant grades and capabilities, please check our dent-resistant steels.

- Applications – CS Type B is a product that is best suited for unexposed applications. These materials work well for applications with very little depth of draw. CS Type B is typically used on truck bed floors and other floor pans with little formability requirements. Other suitable parts are truck cab backs and tailgate access covers.

APPLICATIONS

- Truck bed floors

- Floor pans

- Truck cab backs

- Tailgate access covers

TYPICAL PROPERTIES FOR cS

| PRODUCT | YIELD STRENGTH | TENSILE STRENGTH | TOTAL ELONGATION (%) | N-VALUE |

|---|---|---|---|---|

| Hot Roll | 230 | 345 | 31 | – |

| Cold Roll | 207 | 304 | 38 | – |

| EG | 210 | 293 | 37 | – |

| HDGI | 269 | 345 | 40 | 0.21 |

| HDGA | 269 | 345 | 40 | 0.21 |

MILD STEEL APPLICATIONS

SUPPORTING AUTOMOTIVE

CUSTOMER SUCCESS.

At U. S. Steel, careful listening, creative thinking and cross-functional collaboration turn better steel into better solutions for our automaker customers.

LEARN MOREOUR PRODUCTS

Whatever your opportunity or challenge, we have a solution. Browse our product categories below to learn more.

NORTH AMERICAN FLAT-ROLLED

PRODUCTS PRICING