The Next Generation of American Steelmaking is BIG and Well Underway - www.ussteel.com

The completion of the Big River 2 (BR2) expansion at U. S. Steel’s Big River Steel Works facility in Osceola, Arkansas, marks a transformative milestone in American steelmaking, setting new standards in both scale and innovation.

U. S. Steel’s multi-billion-dollar investment in Big River Steel Works since 2019 has nearly doubled Big River Steel’s production capacity from three to six million tons annually. Combined, both complexes can now make just about every single steel product in coil form imaginable. These highly engineered, sustainably made products are ready to supply to our customers – both current and potential.

An expanded offering for growing markets

The increased production capacity and technological advances brought by the BR2 expansion will expand our customer base.

Heading into 2026, we’re targeting the automotive, appliance, solar and construction markets. On-site finishing capabilities such as our three highly advanced continuous galvanizing lines, our non-grain oriented (NGO) electrical steel line, a paint line, and more make ordering from Big River Steel even more convenient, attractive, and value-added.

Sustainability also remains central to Big River Steel Works’ identity and a differentiator for our customers. As the first steel mill in North America to earn ResponsibleSteel™ certification, Big River Steel continues to set the pace for lower-emissions, high-performance steelmaking. And our innovative mix of sustainably produced steels such as verdeX® steel and InduX™ electrical steel demonstrate how world-class steel can be produced responsibly while meeting the evolving expectations of customers, communities and global supply chains.

A one-of-kind ESP line to meet technical demands

Steel is no longer the commodity it was years ago. Today, steel is a highly engineered material made to order to meet our customers’ specialized needs. And chief among those needs: stronger, lighter, more ductile, and more durable steel with tight tolerances. Customers are also increasingly looking for a reliable, resilient supply chain and they prefer coils that are finished right off the line – no additional processing needed.

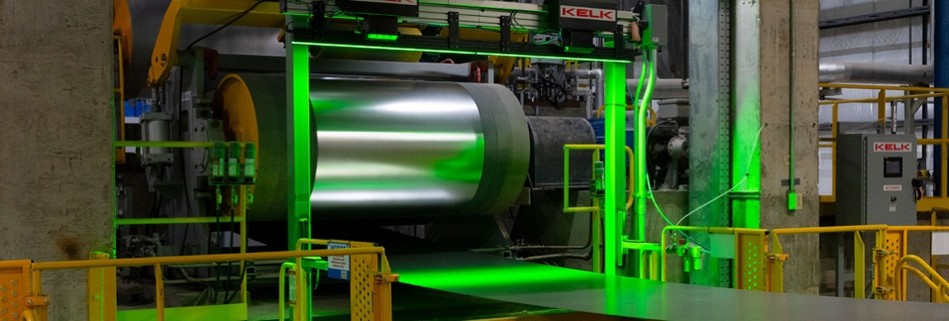

The expanded Big River Steel Works campus meets those needs thanks in part to the only endless steel processing (ESP) line in North America. The ESP is a caster and hot rolling mill combined, capable of taking a 200-ton batch of steel from red-hot liquid form to cooled, rolled coil ready for customer use in as little as 25 to 30 minutes.

Because of the ESP we’re able to produce hot-rolled steel at lighter gauges with exceptionally uniform properties. In fact, customers are telling us that the steel from the ESP is some of best product they’ve ever seen.

A partnership that advances our vision

U. S. Steel’s partnership with Nippon Steel has the potential to transform our company and the American steel industry, and the team at Big River Steel Works is already seeing some of those opportunities become realities. Nippon Steel’s team is helping us get further ahead in non-grain-oriented electrical steel production and are also supporting automotive-grade development with better chemistries and operational improvements. And while one of Nippon Steel’s areas of expertise lies in the blast furnace operations at the heart of much of our company’s steelmaking footprint, their deep bench of highly knowledgeable and experienced engineers is already identifying ways for Big River Steel Works to improve – from electric arc furnace steelmaking to finishing.

A more complete footprint across North America

Looking more broadly, the expanded Big River Steel Works truly rounds out the entire U. S. Steel portfolio. Our integrated plants continue to offer an enduring legacy of high-quality steelmaking, producing critical grades still only capable through the blast furnace process. And now with a more complete footprint in one location, our mini mill segment can serve a broader range of customers in more complete ways while also giving our company added flexibility when a situation calls for it. Finally, with its DRI-ready capabilities, the expanded Big River Steel Works will support our commitment to Mined, Melted and Made in America by making even greater use of the vital iron ore resources controlled by our Minnesota Ore Operations facilities.

Local investment, enduring impact

Finally, we can’t forget the positive impact the Big River Steel expansion is having on Mississippi County and surrounding areas of northeast Arkansas. Our $3 billion investment in BR2 is the largest in state history. In addition to thousands of construction jobs over a two-and-a-half-year period, the project is creating and supporting permanent jobs, growing the local tax base, employing local suppliers and drawing additional companies to invest in the region. U. S. Steel has also contributed $2.6 million to schools, health care infrastructure and first responders. Employee giving and volunteerism will continue to be central to our commitment to the region because as we say here: Big River Cares!

An exciting time for steel

If you think back to 30 or 40 years ago, it’s fair to say that steel was a commodity-type industry. But the recently completed expansion at Big River Steel Works is proof that steelmaking belongs in the larger, global conversation about industrial innovation. As we invite our customers to discover what we can do for their business, we also encourage the nation to stay tuned for what the next generation of American steel has to offer.