Sustainability - Environmental - Energy Conservation - www.ussteel.com

Environment

Energy

Conservation

Energy conservation is good for the environment and our business.

U. S. Steel is a historic innovator and leader in the energy-efficient production of steel using blast furnaces. We also recognize the synergies between the integrated route and EAF techniques that reduce our carbon footprint and optimize operations.

Our published 2050 Roadmap shows our continued commitment to moving toward more energy-efficient processes at our facilities and researching and analyzing new technologies.

Our Climate Strategy Report ensures transparency for our climate-related activities and energy conservation projects by sharing information with relevant stakeholders, including customers, employees, and the communities where we operate.

Energy reduction projects are a key component to meeting our 2030 20% GHG emissions intensity reduction goal, especially at our mining, steelmaking, and finishing operations. Energy reductions can lead to Scope 1 emission reductions (less combustion of natural gas or carbon) as well as Scope 2 emission reductions (reduction in purchased electricity).

Besides capital improvements, we can also improve energy efficiency through process innovations, such as the Blast Furnace Thermal Control Model or-hot Strip Mill Thermomechanical Control Model and our relationships with different university consortia and U. S. Department of Energy projects.

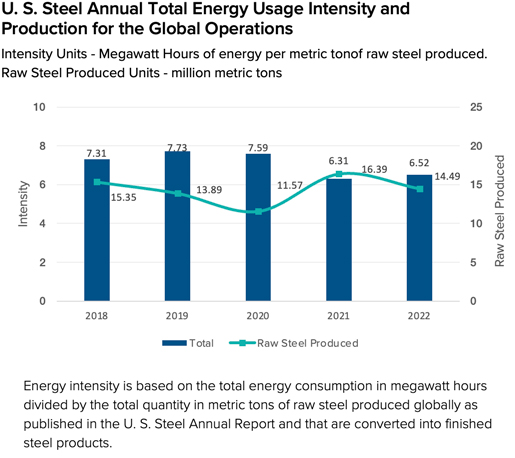

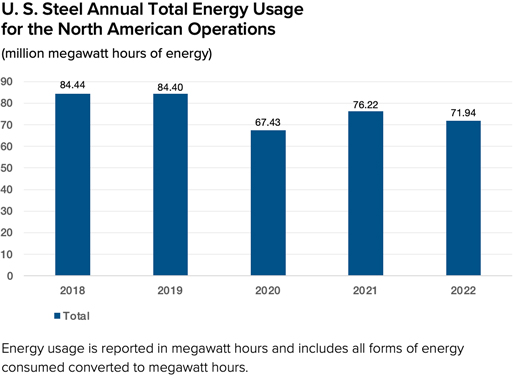

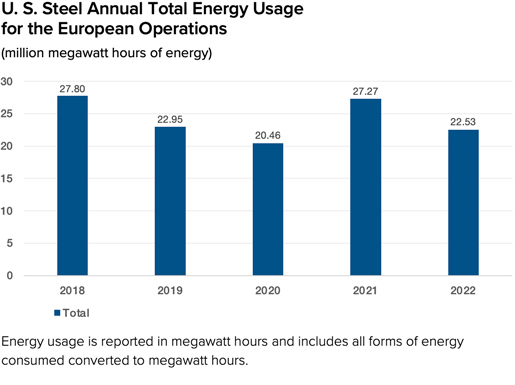

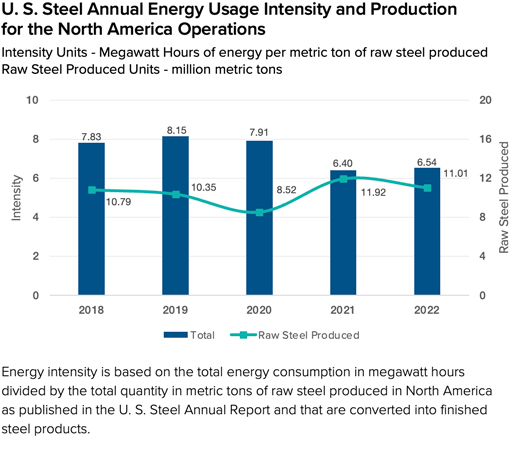

2022 TOTAL ENERGY USAGE

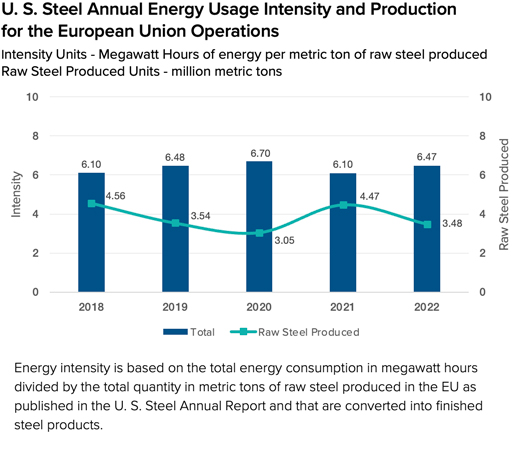

The graphs below show energy use from 2018 – 2022. Our use is reported in megawatt-hours, while our intensity is megawatt hours normalized by raw steel production. Note: Similar to our greenhouse gas emission reportion, for our energy consumption we included not just our steelmaking operations, but also our stand-alone mining and finishing operations.

Spotlight: Energy Conservation Projects

GARY WORKS

NATURAL GAS REDUCTION

An expert control system was commissioned to reduce variations in iron production at the plant’s blast furnace operations. The result: Natural gas consumption dropped approximately 2%.

U. S. STEEL KOŠICE

ELECTRICITY REDUCTION

In 2017, U. S. Steel Košice started a program to replace high-energy/high-maintenance fluorescent lights with LED technology. Through 2019, the facility has reduced electricity consumption by 3,690 MWh per year, achieving a reduction of 1,100 tonnes of greenhouse gas emissions annually.

2022 Energy Summary

Environmental Areas of Focus

U. S. Steel’s current environmental areas of focus align with the results of our ESG Materiality Assessment.